- All construction is completed in our factory which translates into a massive reduction in construction soft costs and reduced on-site labor hours (faster schedule & increased IRR).

- Architecture is pre-approved at the state level via Housing Community Development (HCD) Factory Built Housing program (FBH). City architectural review is limited to site plan layout and unit attachment to foundation.

- Factory built housing allows developers to achieve large production housing economies of scale and volume discounts.

- Near-zero waste technology (savings of 2.3 tons of CO2 emission per 3D printed home). Insurance premiums are generally 10% lower (homes are constructed with non-combustible materials).

- Ability to partner with land holders at the equity level and or provide flexible payment terms once the unit is delivered.

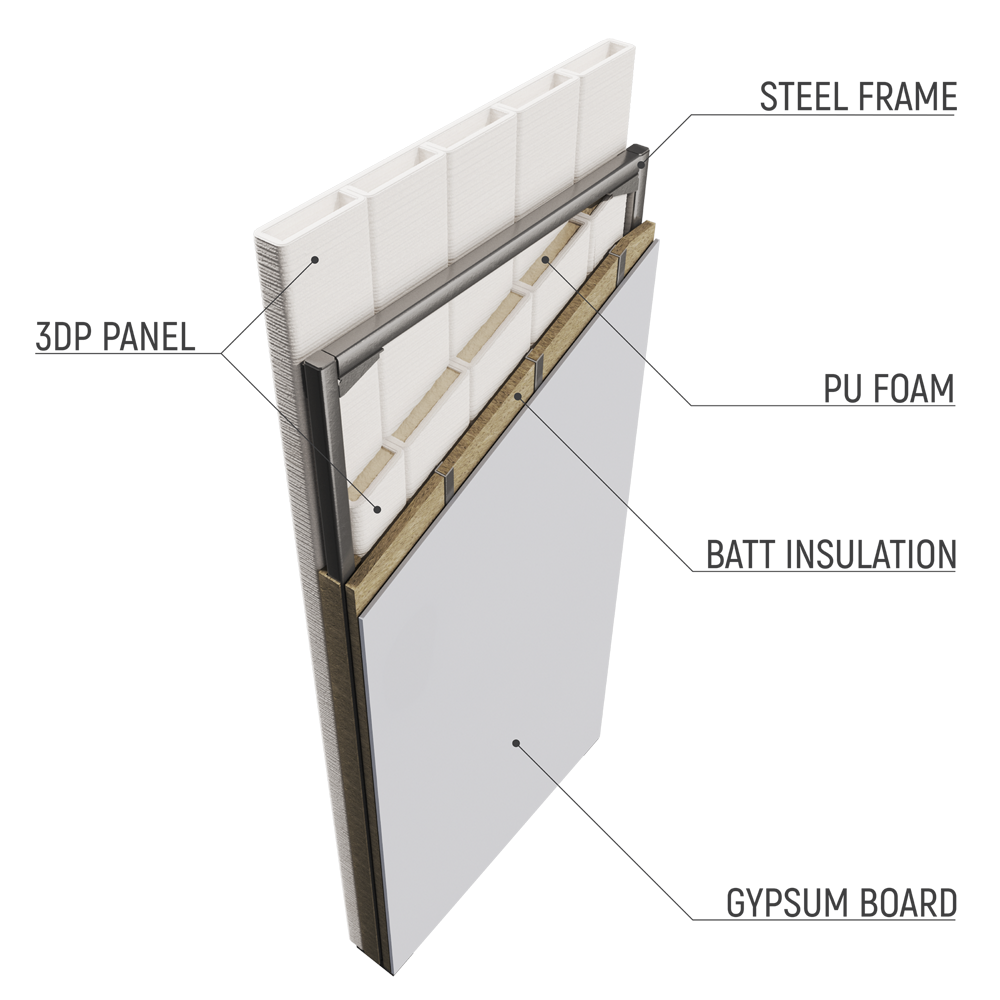

Our patented and certified Mighty Kit System (MKS) made out of our 3D printed panels are unlike any other wall system in the industry. Each panel uses a revolutionary non-silicate Light Stone Material and steel components. This building material provides a high-performance, sustainable, durable, and cost-efficient solution for construction across the United States.

The one of a kind Mighty Kit System makes transporting large units simple from creation to installation. On-site installation has never been easier or more affordable.